Check valve

Efective internal and reverse valve system is hard to imagine without check or shut-off valves. This are two names of the same element which is inteded for blocking sewer flow. Besides this element is using for preventing from entering indoors mice, rats and insects.

Feature of the work of check valve is it’s automation. In case of backflow element will block the sewer on its own. As in working with any other mechanism for error-free and effective service of the element, you should definitely familiarize yourself with the operating instructions, follow the maintenance specified by the manufacturer and also learn what the check valve is made of.

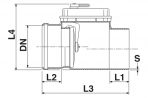

Check valve components and their application:

- Revision cover. Needed for purpose of assessing the technical condition of the object, planned and preventive works.

- Bolts for fastening. Contribute to hermetic installation of the cover.

- Locking valve. It is required in case of emergency closing of the elemnt.

- Seal ring. Due to the special form, not only ease installation is guaranteed but also increased tightness of the device. During assembly, the seal “lies” flat which guarantees the possibility of reassembling the pipeline if necessary.

- Capacity for revision. Provides an opportunity to carry out planned preventive manipulations.

- Locking lever. Allows you to control the valve, directing the flow in the desired direction or keeping the element in a closed state.

- Latch with rubber ring. Needed for complete sealing and maximum reliability.

Getting started and using the equipment

Follow the instructions for attaching internal and external sewer networks. According to the instuctions the valve should be mounted on the horizontal pipeline strictly in horizontal posotion. It is very important to install the valve near the point of introduction of the pipe into the central sewage system with the capability to connect to the network in flow direction.

IMPORTANT! Before starting the installation to make sure in:

- Cleanliness and absence of water on the smooth end bell (you can additionally wipe the surface with a dry cloth)

- There is no damage and correct assembly of the locking mechanism

- Absence of foreign elements in the pire

A silicone emulsion or oil is recommended to lubricate the smooth end of the equipment and the ring in the valve socket.

For the correct installation it is needed to apply an installation mark, which will demonstrate the maximum possible entry of the smooth end of the equiepment into the socket. To do this insert the smooth end of the shaped part into the socket and apply mark. After that the smooth end should be removed out of the socket for a distance of about 1 centimeter and fixed in this position.(do not forget about compensation for temperature elongation)

The shut-off valve should be installed in the flow direction. If a reverse flow occurs, the shut-off valve will operate automatically shut off the sewage system. You can block the flow by turning the valve perpendicular to its movement.

Maintenance

Every six months the locking mechanism needs special cleaning. To do this you need to unscrew the revision cover and clearly wipe the valve elements. If parts that have become unusable are found, they should be pulled out and replaced with the new ones. The equipment can be operated at a temperature not exceeding 67°C.

Proper storage

The best way to store the shut-off valve is in the packaging provided by the manufacturer. The element must be protected from ultraviolet light, moisture and mechanical damage. Make sure that the equipment is not closer than one meter from the heating system.

| DN | S | L1 | L2 | L3 | L4 | Manufacturer |

|---|---|---|---|---|---|---|

|

50 |

2,5 | 50 | 50 | 200 | 90 | Mplast (Ukraine) |