Inspection well

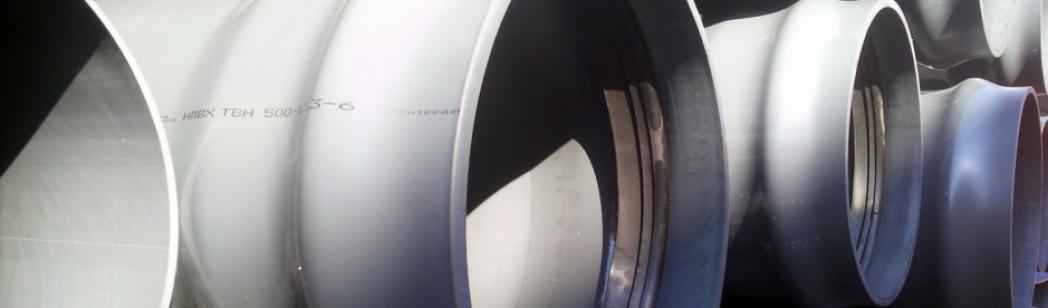

An inspection well (sink) is necessary for carrying out inspection work from the surface of the earth: cleaning, flushing and monitoring the condition of pipes. Thanks to this device, it is possible to timely identify and correct a problem in a sewer pipe made of PVC, PP or PE, which, accordingly, will increase its service life and quality of work. Inspection wells are manufactured with an outer trunk diameter of 315 and 400 mm.

Installation

According to the rules, the inspection well is installed in the most vulnerable places: where the pipe makes a turn, at the junction of two different elements, in places on slopes. If there is a long and straight section of pipe, it is recommended to install inspection wells one from the other at a distance of 20 meters.

Design

What does a manhole consist of? The inspection well has three basic components: a well base with an internal profile (kinet), a PE pipe with smooth walls, which makes up the well trunk and its hatch.

Advantage

One of the main advantages is ease of installation. Even one person can handle the task, which will significantly save resources on attracting additional workers. This opportunity is provided by the light weight of the product.

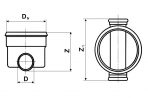

Passage kineta

| D s | D | Z | Z 1 | Manufacturer |

|---|---|---|---|---|

| 315 | 160 | 355 | 600 | Mplast (Ukraine) |

| 315 | 200 | 355 | 600 | * |

| 400 | 160 | 495 | 650 | Mplast (Ukraine) |

| 400 | 200 | 515 | 750 | * |

| 400 | 250 | 715 | 850 | * |

| 400 | 315 | 715 | 1070 | * |

| 400 | 400 | 720 | 1075 | * |

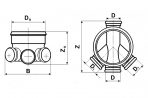

Combined kineta

| D s | D | D1 | Z s | Z | Manufacturer |

|---|---|---|---|---|---|

| 315 | 160 | 160 | 355 | 600 | Mplast (Ukraine) |

| 315 | 200 | 200 | 355 | 600 | * |

| 400 | 160 | 160 | 465 | 655 | Mplast (Ukraine) |

| 400 | 200 | 200 | 505 | 755 | * |

| 400 | 250 | 250 | 715 | 855 | * |

| 400 | 315 | 315 | 715 | 1075 | * |

| 400 | 400 | 400 | 730 | 1079 | * |