Gate valve

A knife gate valve is used to shut off the flow of any characteristics – hard elements, flows with abrasive particles, increased viscosity, with an increased level of crystallization, powdery, fibrous, granular and those that can be chemically active.

Description and components of a gate valve

The main element of equipment is a sliding knife, working in narrow guides which task is to regulate the closure of the rod and body made of PVC material.

A sharp knife, sharpened along the bottom edge cuts the working area, allowing the valve to open or reliably lock when necessary. Proper closure is facilitated by the polished surface of the product, made of stainless steel. The pressure that presses the knife against the seal ensures complete tightness and reliability. Tightness is also ensured by the presence of a valve seal.

Our company can fulfill individual orders for the lenght of the control rod, manufacturing it according to wishes for the convenience of customers and the possibility of using the valve at a depth of up to six meters. This design of knife gate valves is suitable if the working area is predominantly viscous of powdery.

The maind advantage of knife gate valves is possibility of continuous operation under conditions that almost no other device can cope with.

Where are gate valves used?

Gate valves are often installed on pipelines where sewerage wastewater flows as well as other – paper, wood or fruit pulp, mine dust, dense viscous liquids(syrups), petroleum products, polymer chips and many others. Widely used in mining and processing or livestock production.

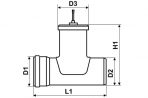

| D1 | D2 | D3 | H1 | L1 | Manufacturer | |

|---|---|---|---|---|---|---|

| 110 | 110 | 110 | 260 | 300 | MPLAST(Ukraine) | |

| 250 | 250 | 293 | 550 | 660 |

|

|

| 315 | 315 | 355 | 650 | 900 |

|