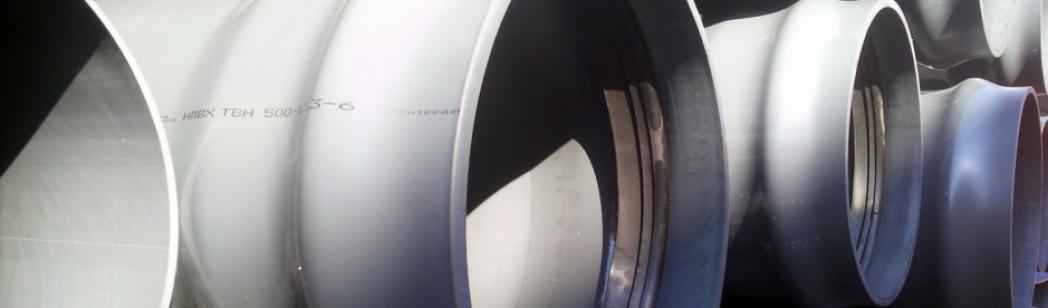

Inspection wells

To clean the sewer system, to notice and prevent problems in the operating system in time, as well as to control the degree of clogging of the system, inspection wells are used. They are installed in the sewerage structure and allow the necessary work to be carried out, including preventive work.

There are several types of inspection wells, and the selection depends on the location of its installation and the purpose of the unit.

-

Pass-through (linear) inspection wells are used for straight sewer areas..

-

Consolidated (node) will help in inspecting places where several pipes are connected at the same time.

-

Differential inspection wells should be installed in places where the level of the inlet and outlet pipe trays is not the same.

-

In places where the pipe makes a turn, appropriate inspection decks are used – rotary ones.

The connection format used in the presence of a gasket ensures the tightness of the inspection well up to 0.5 bar. The presence of stiffening ribs allows the constituent elements to obtain better strength and resistance to groundwater, even when they rise up to 5 meters.

How to install a manhole?

First, the soil should be compacted with a cement composition. Next, the bottom of the well, an intermediate ring of the required height and a hemisphere (cone) are installed.

It is important to leave about 5 centimeters at the top of the hemisphere for the hatch that will be installed on top. Next, use screws to secure the polymer type hatch to the hemisphere, which is brought out at ground level.

What does a manhole consist of?

The tray – the bottom of the well, the intermediate ring and the hemisphere with a neck – are the main components of the device.